Modern vehicles are becoming increasingly sophisticated, presenting new obstacles for technicians who must keep pace with rapid technological advances. This article explores practical strategies to address these training challenges, drawing on insights from industry experts. Readers will learn about protected learning time, modular education approaches, and AI-assisted standardization techniques that can transform technician development.

- Standardize SOPs with AI Guidance

- Provide Protected Time and Mentorship

- Adopt Continuous Modular Education

Standardize SOPs with AI Guidance

The biggest challenge in training technicians for increasingly complex vehicles isn’t a lack of talent. It’s the growing gap between how fast vehicles are evolving and how slowly traditional training systems adapt.

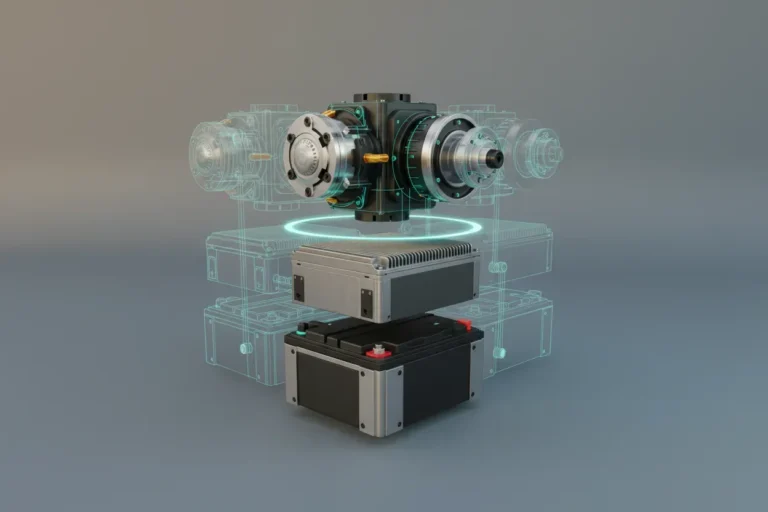

Modern vehicles are no longer just mechanical. They’re rolling networks of software, sensors, electrical systems, and tightly integrated subsystems. Expecting technicians to keep up using static manuals, infrequent certifications, or tribal knowledge simply doesn’t scale.

The solution starts with process and systemization.

Clear, well-documented SOPs are the foundation. When every diagnostic step, installation process, and quality check is standardized and documented, complexity becomes manageable. Consistency reduces errors, shortens onboarding time, and creates confidence for technicians working on unfamiliar systems.

At The Vansmith, we’ve seen firsthand how critical this structure is when working on modern transit and adventure vehicles that combine electrical, mechanical, and software-driven systems.

Training must also evolve beyond classrooms and PDFs. This is where AI becomes a force multiplier. Short, task-specific AI-assisted training videos can show technicians exactly how to perform a procedure, not just describe it. Best-practice libraries can be built from real-world jobs, capturing what actually works and making that knowledge instantly searchable.

Most importantly, training needs to happen in real time. When a technician encounters a new system or edge case, they should be able to access guidance at the moment they need it. AI-driven tools can surface relevant SOPs, videos, and past solutions on demand, turning every job into a learning opportunity rather than a slowdown.

The future of technician training isn’t about longer certifications or more paperwork. It’s about building living systems that learn, adapt, and improve alongside the vehicles themselves. When process, documentation, and AI-powered learning work together, complexity stops being a barrier and becomes a competitive advantage.

Provide Protected Time and Mentorship

The challenge is around current vehicles, as it becomes layered faster than technicians can realistically be trained.

Technicians nowadays no longer work on a single system in isolation. You see, a drivability issue might start in a sensor then travel through software, and show up as a mechanical symptom. That kind of complexity takes time to understand, but most shops are still built around speed.

The expectation is to diagnose quickly, fix quickly, and move on, which leaves very little room for learning why something failed in the first place. And over time, it creates technicians who can swap parts but don’t feel fully confident in what they’re chasing, and that’s where frustration and burnout start to creep in.

The solution I think is to treat training as part of the job. Technicians need protected time to learn systems the right way, access to real diagnostic tools, and mentorship from experienced technicians who can explain why a system behaves the way it does. Yeah, I think that’s the simplest way to tackle it. Give people the space to actually understand what they’re working on, and they’re far more likely to stick with it as the vehicles keep getting more complex.

Adopt Continuous Modular Education

The biggest challenge in training technicians for increasingly complex vehicles is the speed at which vehicle technology is evolving; it means training programs cannot keep up. Technicians are no longer just working on mechanical systems but increasingly are required to understand advanced electronics, software diagnostics, telematics, ADAS systems, alternative powertrains, and sometimes even hybrid or electric platforms. Yet many training and apprenticeship programs are still built around the yesteryear of older vehicle architectures. This leads to a skills gap practically as soon as a technician enters the workforce.

A further issue is that many modern vehicles now require OEM (Original Equipment Manufacturer)-specific software, subscriptions, and diagnostic tools. Most smaller fleets just cannot afford all of these.

The solution is constant learning – continuous, modular training – to provide technicians with access to short, targeted training materials that are tied to real vehicle data and systems. Unless ASE training moves at the same pace that vehicles themselves are changing, then the skills gap will keep widening.